Coil strip handling line

RNM

Coil strip handling line

RNM

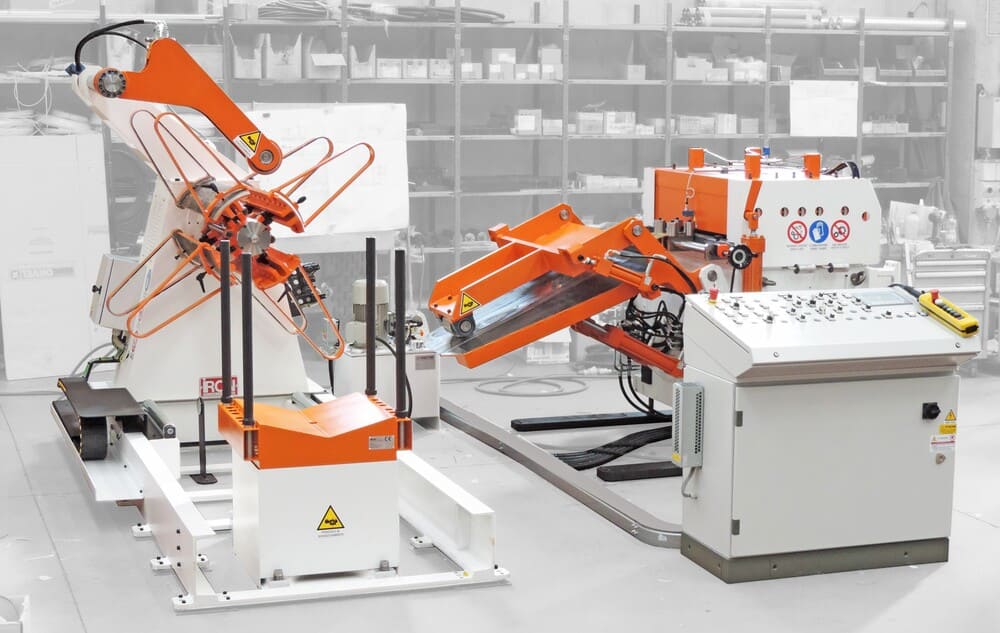

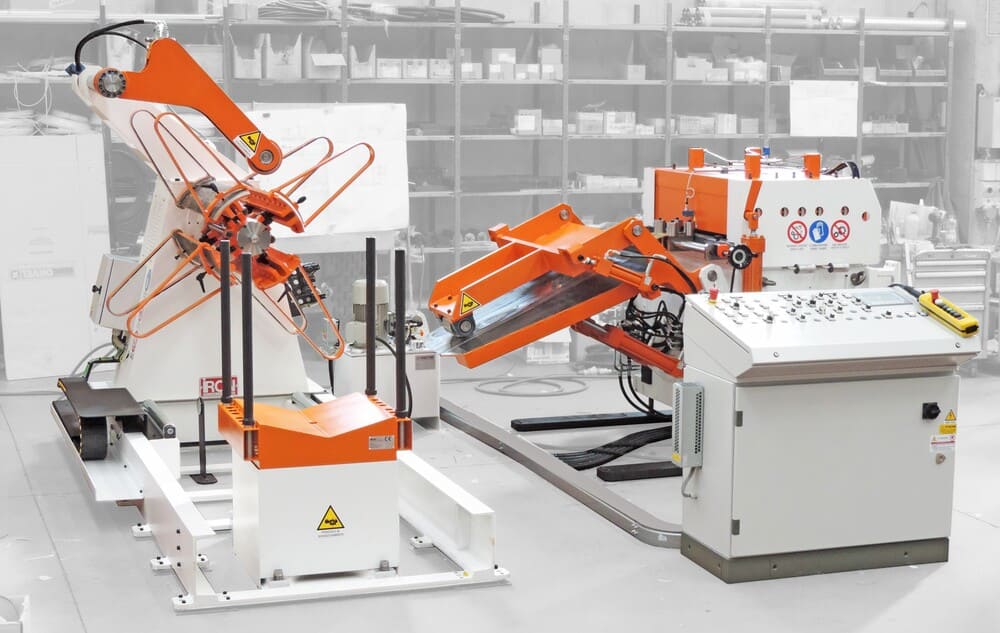

RNM is a coil strip handling line with a compact design, created to meet the needs of reducing space in the workshop. It primarily consists of an uncoiler and a straightener/feeder.

A customizable coil strip handling line

The system is customizable, offering the client a broad range of accessory options:

Loading cradle for coils series CS and CST

Alignment slide for decoiler series SAT

Pressure arm for coil holding series SBPOM

Coil containment rollers series RLR

Head introduction group for the coil, UPR series

Hydraulic/pneumatic head opening device for pilot centering, ATO and ATP series

Motorized and independent adjustment of straightening rollers, with display and memory on a lectern series RMR - Book-opening head device to facilitate roller cleaning series ATL

Motorized height adjustment device, RAMO series

The main components of our coil strip handling lines RNM

The uncoiler

All our uncoilers are equipped with four self-centering clamps with hydraulic expansion. The diameter for handling rolls is based on the customer’s needs, typically 508 mm (20”) or 610 mm (24”). They are produced with variable capacities for coils weighing 2, 4, 6, 10, and 15 tons. They are manufactured in two versions: INV Series for uncoilers controlled by an inverter and a timed photocell for loop control.

They are equipped with a worm gear reducer with an overload clutch. ENC Series for uncoilers controlled by an inverter and feedback encoder. This solution allows the use of the uncoiler in controlled electrical braking. They are equipped with an epicyclical reducer. And can be supplied in a single spindle (SA) or double spindle (SAD) version.

They are equipped with a worm gear reducer with an overload clutch. ENC Series for uncoilers controlled by an inverter and feedback encoder. This solution allows the use of the uncoiler in controlled electrical braking. They are equipped with an epicyclical reducer. And can be supplied in a single spindle (SA) or double spindle (SAD) version.

The straightener/feeder

All our straighteners/feeders are equipped with 11 rollers:

- 2 feed rollers at the entrance,

- 7 straightening rollers,

- 2 feed rollers at the exit.

All rollers are made of quality 100CR6 steel, hardened, and ground (hard chrome plating is available upon request). Built in 5 diameter versions, 66, 76, 86, 96, and 126 mm. The adjustment of the feed and straightening rollers is manual and independent. At the entrance of the straightener/ feeder, there is a roller guide tape that maintains alignment to the mold. The adjustment is manual (motorized type is available upon request). The lubrication of the chain and gears is guaranteed by timed cartridges. It is equipped with a Siemens electronic package, consisting of a KP700 control and SIEMENS 1500 TA PORTAL PLC, digital brushless motor, SINAMICS drive, encoder, and operator interface with a 7’’ backlit LCD touch screen.

- 2 feed rollers at the entrance,

- 7 straightening rollers,

- 2 feed rollers at the exit.

All rollers are made of quality 100CR6 steel, hardened, and ground (hard chrome plating is available upon request). Built in 5 diameter versions, 66, 76, 86, 96, and 126 mm. The adjustment of the feed and straightening rollers is manual and independent. At the entrance of the straightener/ feeder, there is a roller guide tape that maintains alignment to the mold. The adjustment is manual (motorized type is available upon request). The lubrication of the chain and gears is guaranteed by timed cartridges. It is equipped with a Siemens electronic package, consisting of a KP700 control and SIEMENS 1500 TA PORTAL PLC, digital brushless motor, SINAMICS drive, encoder, and operator interface with a 7’’ backlit LCD touch screen.

For additional details, please see our brochure.

Via E. Fermi, 20 / Via Ungheresca Nord, 9 - 31010 Mareno di Piave (TV) IT

+39 0438 492390

ironinfo@iron.it

Società con unico socio

Capitale sociale € 100.000,00 i.v.

Registro Imprese TV – C.F. e P.IVA: IT04188760260

R.E.A. TV 330275

COD. MECC. TV 054072

Capitale sociale € 100.000,00 i.v.

Registro Imprese TV – C.F. e P.IVA: IT04188760260

R.E.A. TV 330275

COD. MECC. TV 054072

Società con unico socio

Capitale sociale € 100.000,00 i.v.

Registro Imprese TV – C.F. e P.IVA: IT04188760260

R.E.A. TV 330275

COD. MECC. TV 054072

Capitale sociale € 100.000,00 i.v.

Registro Imprese TV – C.F. e P.IVA: IT04188760260

R.E.A. TV 330275

COD. MECC. TV 054072

Prodotti

Products

Vuoi rimanere aggiornato su tutte le nostre novità?

Want to stay up-to-date on all our news?

Iscriviti alla newsletter: riceverai tutti i nostri consigli e le ultime novità!

Sign up for our newsletter: you will receive all our tips and the latest news!